The Mercedes blind spot sensor alignment is a critical safety feature that ensures accurate detection of vehicles in blind spots during lane changes. Regular calibration and testing are vital to prevent accidents, with recurring alerts indicating misalignment caused by wear, debris, or repairs. Professional recalibration using specialized equipment is needed for precise data, enhancing safety in bustling environments. Post-alignment, rigorous testing and bodywork inspections verify functionality and aesthetic appeal.

Mercedes vehicles are equipped with advanced safety features, including blind spot sensors, crucial for maintaining awareness during lane changes. However, over time, these sensors may require recalibration due to factors like tire rotation or vehicle damage. Understanding when and how to align your Mercedes’ blind spot sensors is essential for optimal system performance. This guide delves into the functionality of these sensors, outlines alignment triggers, and provides step-by-step testing and realignment procedures for a recalibrated driving experience.

- Understanding Mercedes Blind Spot Sensor Functionality

- When Alignment Is Necessary for Recalibration

- System Testing and Realignment Steps After Alignment

Understanding Mercedes Blind Spot Sensor Functionality

The Mercedes Blind Spot Sensor is a sophisticated piece of technology designed to enhance driver safety by monitoring the vehicle’s surroundings. These sensors detect vehicles in the blind spot region, typically found around the car’s rear and side, where visibility may be limited for the driver. When activated, the sensor sends signals to the vehicle’s control unit, which then takes appropriate action to alert the driver or even make corrective maneuvers. This real-time detection system is crucial for preventing accidents, especially during lane changes.

Regular calibration ensures the Mercedes Blind Spot Sensor functions optimally. Over time, factors like environmental conditions, road debris, or auto glass repair can impact its accuracy. Therefore, when a driver notices repeated alerts despite not changing lanes, it may indicate a need for alignment and recalibration. A professional mechanic can perform this task, aligning the sensors to ensure they provide accurate data for reliable performance, just as one would maintain a classic car restoration by bringing every component back to its prime condition.

When Alignment Is Necessary for Recalibration

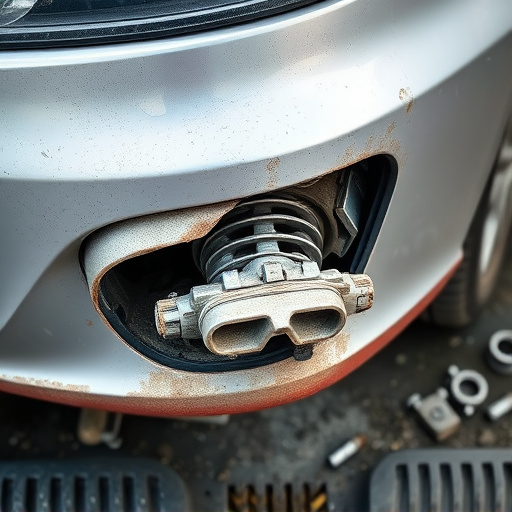

The Mercedes blind spot sensor alignment is a critical process that becomes necessary when the system requires recalibration. Over time, these sensors, designed to detect vehicles in adjacent lanes and warn drivers of potential collisions, can drift out of their calibrated positions due to various factors. These include but are not limited to regular wear and tear, road debris impact, or even slight adjustments made during routine auto body services. A collision repair shop with specialized equipment is often required to perform this alignment accurately.

When a driver notices recurring warnings from the blind spot sensors despite consistently checking their mirrors, it may indicate a need for recalibration. Other signs include sensor malfunction during lane changes or when the vehicle’s side mirror adjustments no longer sync with the sensor’s readings. Prompt attention to these issues is essential as they can significantly enhance road safety, especially in bustling environments where quick reaction times are vital.

System Testing and Realignment Steps After Alignment

After completing the Mercedes blind spot sensor alignment, it’s crucial to verify the system’s functionality through rigorous testing. This involves simulating various driving scenarios, including lane changes and overtakes, to ensure the sensors accurately detect and respond to vehicles in adjacent lanes. Advanced diagnostic tools can be employed to monitor real-time sensor data, allowing for precise adjustments if needed.

During this process, it’s recommended to inspect the car bodywork services, particularly around the blind spot areas, for any signs of damage or misalignment that might have occurred during the alignment procedure. In cases where the car body repair is necessary, a professional automotive restoration specialist can ensure that all components are correctly repositioned and sealed to maintain optimal sensor performance. This step guarantees that the Mercedes blind spot sensor alignment is not just technical but also aesthetic, providing both safety and visual appeal.

Mercedes Blind Spot Sensor (BSS) alignment is a crucial step in maintaining optimal system performance. Knowing when realignment is necessary, as discussed in this article, ensures that your vehicle’s BSS functions at its best. By understanding the functionality of these sensors and following the proper testing and realignment steps, drivers can enhance their safety and driving experience. Regular maintenance of the blind spot sensor alignment is a simple yet vital task for any Mercedes owner.