Mercedes blind spot sensor alignment is vital for safety and performance. Factory equipment ensures precise adjustments, guaranteeing accurate hazard detection. Specialized tools calibrate sensors perfectly, considering model-specific factors, leading to top-notch functionality across all Mercedes models. Regular maintenance by authorized services enhances road safety, reduces the need for car dent removal, and prevents costly bumper repairs.

Mercedes vehicles are equipped with advanced safety features, including blind spot sensors, crucial for preventing accidents. This article delves into the intricate process of aligning these sensors using factory equipment. We explore the significance of proper alignment and its impact on vehicle safety. Understanding how factory tools ensure optimal performance can help drivers make informed decisions regarding their car’s maintenance. From sensor functionality to precise alignment techniques, this guide offers valuable insights for Mercedes owners.

- Understanding Mercedes Blind Spot Sensor Functionality

- The Role of Factory Equipment in Alignment Process

- Ensuring Optimal Performance: Alignment Techniques

Understanding Mercedes Blind Spot Sensor Functionality

The Mercedes blind spot sensor is a sophisticated safety feature designed to significantly enhance driving awareness and prevent accidents. These sensors detect vehicles in the driver’s blind spots, typically located on the sides of the car, and provide real-time warnings through visual or auditory cues. When a vehicle enters the driver’s blind area, the sensor aligns itself with the car’s side mirrors to offer precise information about the proximity of nearby objects. This alignment ensures that drivers can easily identify potential hazards without having to turn their heads or rely solely on mirrors.

Proper Mercedes blind spot sensor alignment is crucial for optimal functionality. Car paint services and repairs sometimes include adjustments to these sensors as part of their comprehensive car care offerings. Through regular maintenance, including the servicing of these sensors by authorized car repair services, drivers can ensure that their vehicles are equipped with the best possible safety measures. This proactive approach not only enhances road safety but also adds value to the vehicle through features like blind spot monitoring, which is increasingly important in today’s bustling traffic conditions. Moreover, it reduces the need for costly car dent removal services that might arise from accidents caused by blind spot sensor malfunctions.

The Role of Factory Equipment in Alignment Process

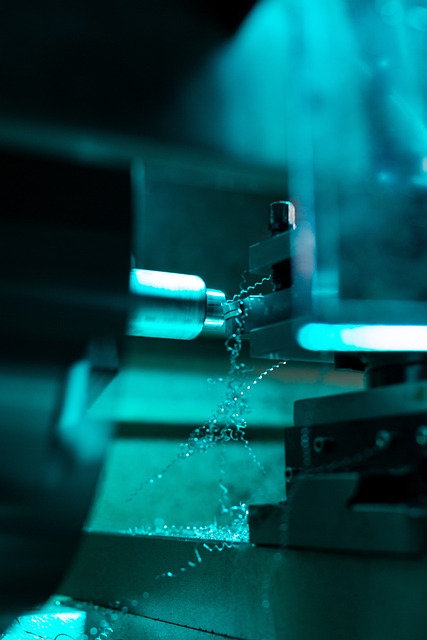

The alignment process for Mercedes blind spot sensors is a critical procedure that relies heavily on specialized factory equipment. These tools are designed to ensure precise adjustments, allowing for optimal sensor performance and enhanced driver safety. By utilizing factory-grade equipment, auto body services can achieve accurate calibrations, ensuring the sensors detect potential hazards accurately and consistently.

This meticulous approach is essential in the automotive industry, where even minor discrepancies can impact vehicle dynamics. Skilled technicians employ these tools to fine-tune the alignment, taking into account various factors unique to each Mercedes model. This attention to detail is a key aspect of quality auto repair services, guaranteeing that every car leaves the workshop with top-notch sensor functionality and overall performance, just like a freshly restored car.

Ensuring Optimal Performance: Alignment Techniques

Maintaining optimal performance for Mercedes blind spot sensors requires precise alignment, a task best accomplished using factory equipment designed specifically for this purpose. Fleet repair services often emphasize the importance of such alignment techniques to ensure each sensor functions at its highest level, enhancing safety and driving experience. This meticulous process involves calibrating the sensors to accurately detect surrounding vehicles, thereby minimizing blind spots and preventing potential collisions.

Proper alignment goes beyond mere calibration, encompassing adjustments to the sensor’s positioning and orientation. Skilled technicians use specialized tools to fine-tune these aspects, mirroring the meticulous craftsmanship employed in Mercedes benz repair. By adhering to these stringent standards, fleet repair services not only uphold the brand’s reputation for quality but also contribute to the overall safety and reliability of each vehicle, addressing issues that might otherwise lead to costly bumper repairs.

Mercedes blind spot sensors play a crucial role in enhancing safety, and their proper alignment is essential for optimal performance. Using factory equipment ensures precise adjustments, guaranteeing these sensors function seamlessly. By employing specialized tools and adhering to strict guidelines, technicians can achieve the best results in aligning Mercedes blind spot sensors, ultimately contributing to safer driving experiences.