The Mercedes blind spot sensor, vital for AMG and EQ models' safety, uses ultrasonic waves or cameras to detect vehicles in drivers' blind spots during lane changes. Regular alignment is crucial as debris, wear, or auto repairs can cause misalignment, leading to detection failures and increased accident risk. Proper maintenance ensures sensors function effectively, enhancing driver awareness and overall safety, supporting vehicle resale value, and preventing costly auto glass repair.

Mercedes vehicles equipped with AMG or EQ models feature advanced blind spot sensors, enhancing safety by detecting nearby vehicles. However, optimal performance requires regular alignment. This article delves into the functionality of these sensors and clarifies when alignment is necessary. We explore how proper calibration optimizes safety, ensuring drivers are aware of surrounding traffic, especially during lane changes. Understanding Mercedes blind spot sensor alignment is crucial for maximizing vehicle performance and passenger security.

- Understanding Mercedes Blind Spot Sensor Functionality

- When Alignment Is Necessary for AMG and EQ Models

- Optimizing Safety with Proper Blind Spot Sensor Calibration

Understanding Mercedes Blind Spot Sensor Functionality

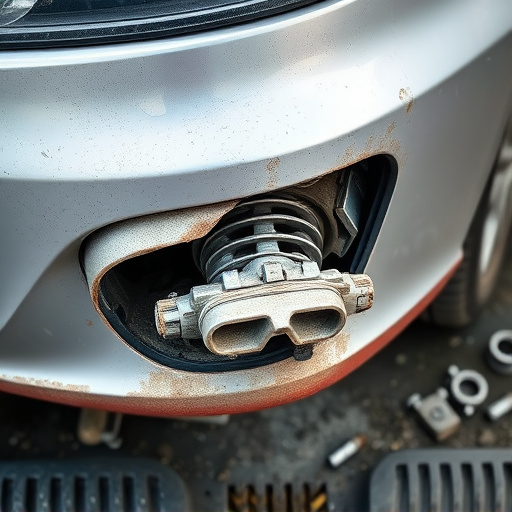

The Mercedes blind spot sensor is a vital component designed to enhance safety and provide drivers with a comprehensive view of their surroundings. This advanced technology uses ultrasonic waves or cameras to detect vehicles in the driver’s blind spots, especially during lane changes. When an obstacle is identified, the system alerts the driver through visual cues on the side mirrors or audio signals, ensuring they’re aware of nearby traffic before making a maneuver.

For Mercedes AMG and EQ models, maintaining proper Mercedes blind spot sensor alignment is crucial for optimal performance. Over time, sensor misalignment can occur due to various factors like damage from road debris, regular wear and tear, or even during vehicle repair or auto glass replacement. An improperly aligned sensor might fail to detect nearby vehicles, leading to potential accidents. Therefore, regular checks and necessary auto repair are essential to keep these sensors functioning at their best, ensuring a safer driving experience for all.

When Alignment Is Necessary for AMG and EQ Models

Mercedes AMG and EQ models are equipped with advanced safety features, including blind spot sensors, designed to protect drivers and passengers from potential vehicle collisions. However, for these systems to function optimally, regular alignment is crucial. Over time, factors like road debris, minor fender benders, or even everyday driving conditions can cause misalignment of the sensors, leading to reduced effectiveness.

When signs of misalignment emerge, such as sensor errors or inconsistent performance, it’s time to consider Mercedes blind spot sensor alignment. Fleet repair services and specialized technicians are equipped to handle this task accurately, ensuring the sensors are precisely calibrated to detect blind spots effectively. Proper alignment not only enhances safety but also supports vehicle resale value by maintaining the car’s overall integrity and aesthetics, even after potential repairs like car dent removal.

Optimizing Safety with Proper Blind Spot Sensor Calibration

Optimizing Safety with Proper Blind Spot Sensor Calibration

In today’s fast-paced world, ensuring maximum safety on the roads is paramount, especially for high-performance vehicles like Mercedes AMG and EQ models. One critical component in achieving this is the blind spot sensor system. These sensors play a vital role in detecting vehicles nearby, particularly in areas not visible to the driver—a feature that can significantly reduce the risk of accidents. However, for these systems to function optimally, regular Mercedes blind spot sensor alignment is essential. A well-calibrated sensor ensures accurate and reliable detection, providing drivers with crucial split seconds to react and make necessary adjustments when changing lanes or merging onto highways.

Proper alignment involves adjusting various components, including the sensors’ positioning and calibration parameters, to match the specific requirements of each Mercedes model. This meticulous process is typically performed by trained technicians in a professional auto body shop or mercedes benz repair center using advanced diagnostic tools. Regular maintenance not only optimizes safety but also extends the lifespan of these critical systems, ensuring they perform at their best for years to come. Moreover, keeping blind spot sensors aligned can prevent costly auto glass repair or replacement, as it minimizes potential damage from collisions caused by driver error.

Mercedes vehicles equipped with AMG or EQ models require regular blind spot sensor alignment to ensure optimal safety. By understanding the functionality of these sensors and addressing alignment needs promptly, drivers can enhance their driving experience and maintain a secure presence on the road. Proper calibration is key in detecting potential hazards, especially during high-speed maneuvers, making it an essential maintenance task for Mercedes owners.