Mercedes Blind Spot Sensor Alignment is a crucial aspect of modern vehicle safety, requiring regular calibration and maintenance by skilled technicians. Any bodywork or tire services should consider their impact on sensor positioning to ensure optimal detection and prevention of accidents. Adhering to OEM guidelines and using specialized equipment for field of view verification enhances both vehicle performance and safety in today's fast-paced traffic conditions. Auto collision repair shops prioritizing these practices build trust with customers relying on advanced driver-assistance systems (ADAS) for their safety.

Mercedes blind spot sensor alignment is a critical component of modern vehicle safety systems. This article delves into the intricacies of maintaining compliance with Original Equipment Manufacturer (OEM) specs for these sensors. By understanding the role of OEM guidelines in sensor positioning and adopting best practices, mechanics can ensure optimal performance and reliability. We explore why adherence to these specifications is essential for effective blind spot monitoring, ultimately enhancing road safety for Mercedes owners.

- Understanding Mercedes Blind Spot Sensor Alignment

- The Role of OEM Specifications in Sensor Alignment

- Ensuring Compliance: Best Practices and Benefits

Understanding Mercedes Blind Spot Sensor Alignment

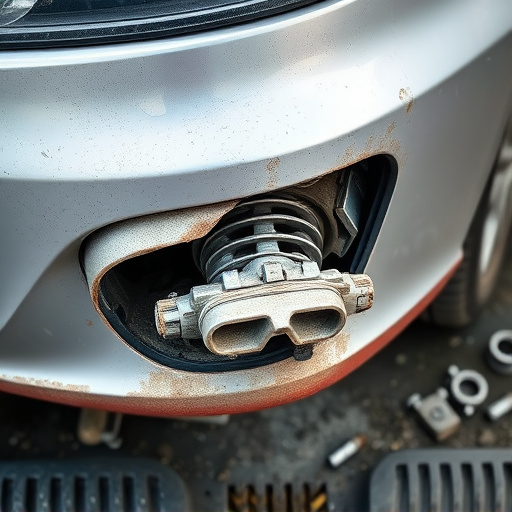

Mercedes Blind Spot Sensor Alignment is a critical aspect of modern vehicle safety systems. These sensors are designed to detect vehicles in adjacent lanes, alerting drivers through visual and auditory cues. Proper alignment ensures that these sensors function optimally, enhancing road safety. Non-compliance with Original Equipment Manufacturer (OEM) specs can lead to false readings or missed detections, compromising the effectiveness of this life-saving technology.

Automotive body shops specializing in tire services and car bodywork repairs play a vital role in maintaining these systems. Regular checks and adjustments are necessary due to potential misalignments caused by accidents, road debris, or normal wear and tear. Skilled technicians use specialized tools to calibrate the sensors precisely, ensuring they align perfectly with OEM specifications. This meticulous process not only maintains safety standards but also guarantees that drivers receive accurate and timely warnings when changing lanes.

The Role of OEM Specifications in Sensor Alignment

In the realm of automotive technology, Original Equipment Manufacturer (OEM) specifications play a pivotal role in ensuring vehicle safety and performance. When it comes to Mercedes blind spot sensor alignment, adhering to OEM guidelines is paramount. These sensors are designed to detect obstacles in the driver’s blind spots, providing critical assistance for lane changes and preventing accidents. Proper alignment guarantees that these sensors function optimally, enhancing the overall driving experience and passenger safety.

Car paint services and body shop repairs often go hand in hand with sensor alignment issues. A dent removal process or other body shop services might inadvertently affect the positioning of blind spot sensors. Therefore, regular maintenance and checks are essential to ensure these sensors remain aligned with OEM specs. This meticulous attention to detail is what distinguishes top-tier car paint services and body shop operations, ensuring both visual appeal and safety functionality.

Ensuring Compliance: Best Practices and Benefits

Ensuring compliance with Original Equipment Manufacturer (OEM) specs is paramount for maintaining vehicle safety and performance, especially when it comes to advanced driver-assistance systems like Mercedes blind spot sensors. Proper alignment of these sensors is crucial to guarantee their effectiveness in detecting potential hazards during lane changes or overtaking maneuvers. Best practices involve regular calibration checks, utilizing specialized equipment to verify the sensor’s field of view and accuracy, and adhering to OEM guidelines for installation and adjustment.

Benefits of maintaining compliance include improved driver awareness, reduced risk of auto collision repair needs, and enhanced overall vehicle value. Auto collision repair shops offering body shop services should prioritize these practices not only for quality control but also to build trust with customers who rely on their vehicles’ safety features, especially in today’s fast-paced traffic conditions.

Mercedes blind spot sensor alignment is crucial for maintaining optimal vehicle safety. By adhering to Original Equipment Manufacturer (OEM) specifications, car owners can ensure that their sensors function at peak performance, providing accurate detection and preventing potential accidents. Regular calibration and maintenance are best practices that offer numerous benefits, including improved driving confidence, reduced risks, and enhanced overall vehicle reliability.